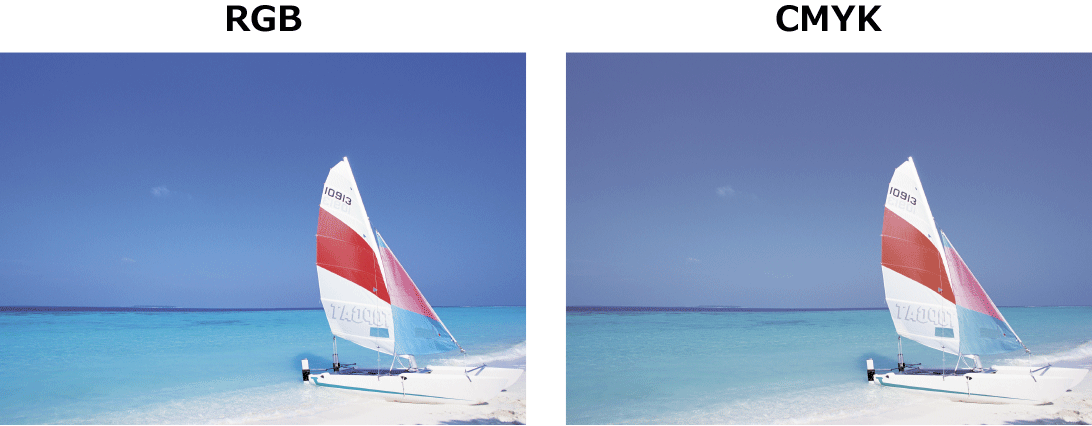

About the difference between CMYK and RGB

Colors that appear vivid on a display (RGB) will appear dark and subdued when printed (CMYK). RGB colors cannot be reproduced by printing, so please be sure to create the data used for printing in CMYK.

The figure below shows RGB and CMYK images before and after conversion. The more saturated the image, the greater the difference.

The figure below shows RGB and CMYK images before and after conversion. The more saturated the image, the greater the difference.

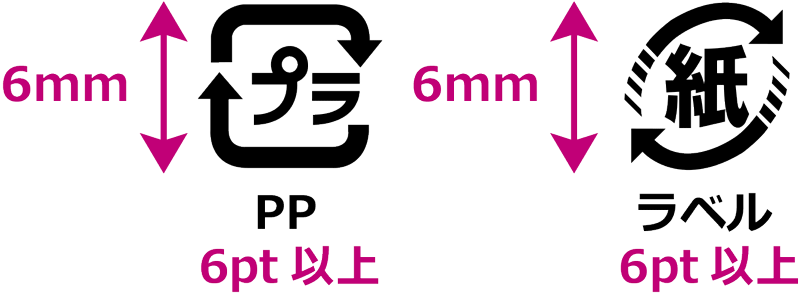

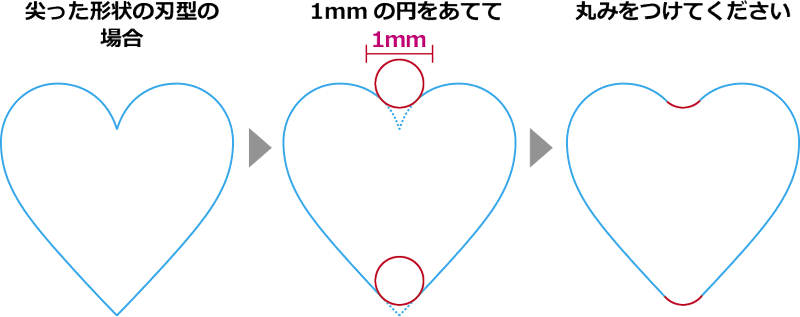

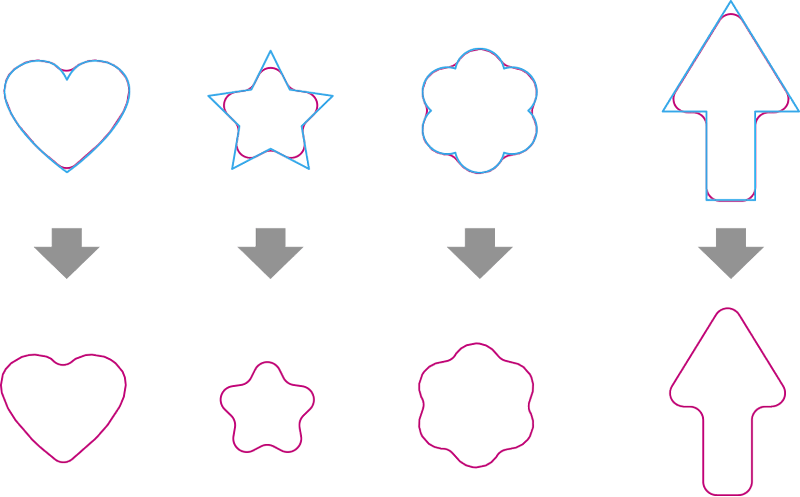

Notes on deformed blade types

For convenience, the edges of the cutting blade are rounded by 1mm, so this must be taken into consideration when creating the blade. In particular, when a small or sharp blade is rounded, the shape may change significantly and the result may be different from what you imagined. please note.

If you attach a 1mm circle (0.5R) to a small, 4-5mm sharp blade such as a notebook sticker, the shape and balance will change dramatically. please note.

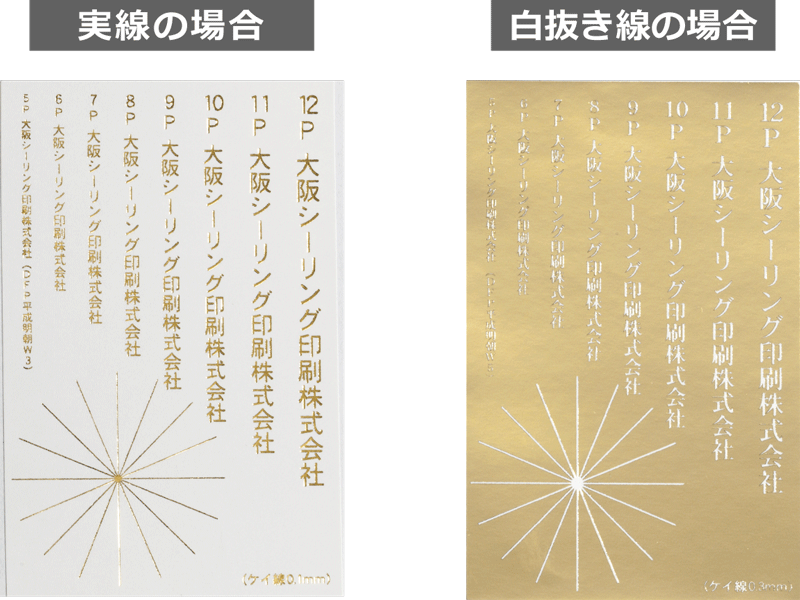

About the thickness of characters and lines

For printing

0.075mm or more is required for solid lines and 0.1mm or more for blank lines.

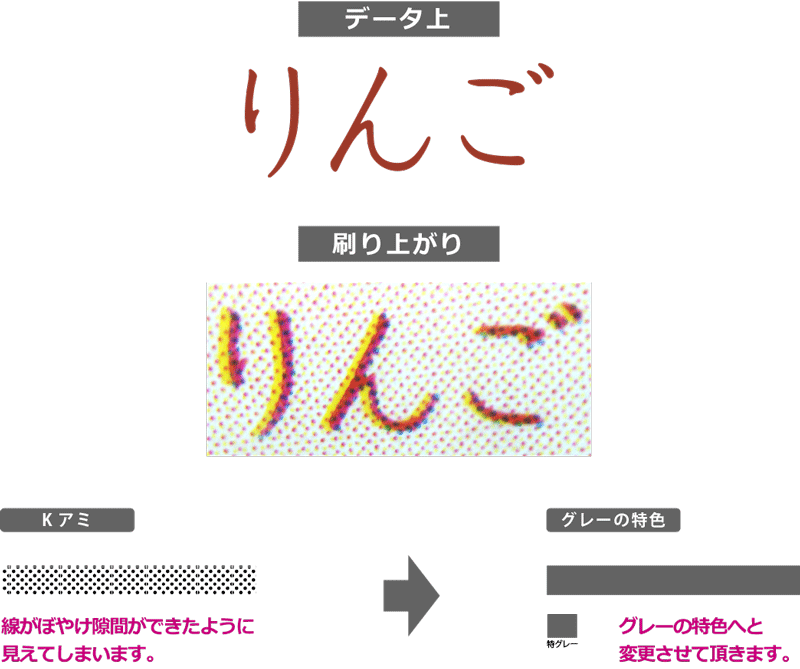

If thin lines or text are mixed colors, misalignment will be more noticeable, and if they are mixed, the lines will become blurred and look like dotted lines. Depending on the situation, we can also suggest changing the color, such as changing the color from a mixed brown to a special brown, or changing the color of K to a special gray.

The photo is an example of printing small letters in a mixed brown color, which caused misalignment.

If thin lines or text are mixed colors, misalignment will be more noticeable, and if they are mixed, the lines will become blurred and look like dotted lines. Depending on the situation, we can also suggest changing the color, such as changing the color from a mixed brown to a special brown, or changing the color of K to a special gray.

The photo is an example of printing small letters in a mixed brown color, which caused misalignment.

- For foil stamping

- In the case of foil stamping, there is a possibility that the lines may become thin or faded, so the thickness of solid lines must be at least 0.1 mm, and the stamped lines must be at least 0.2 mm.

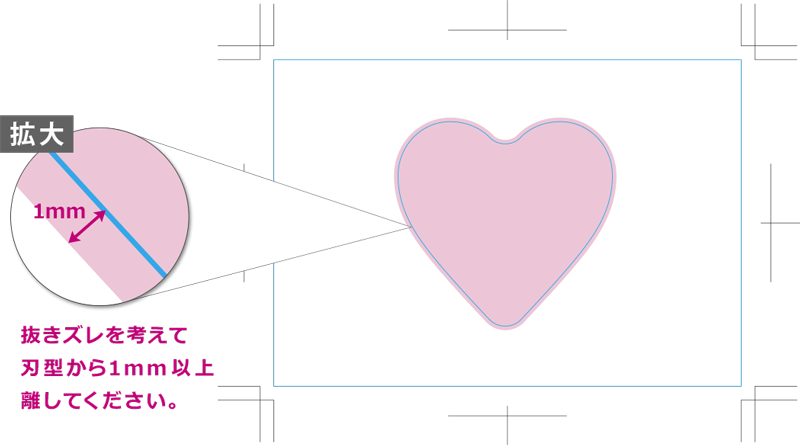

About refilling

In consideration of the possibility of misalignment when cutting out with the blade die, please add at least 2mm more than the edge of the die.

If there are cutouts on the inside of the blade shape, you will also need to reapply.

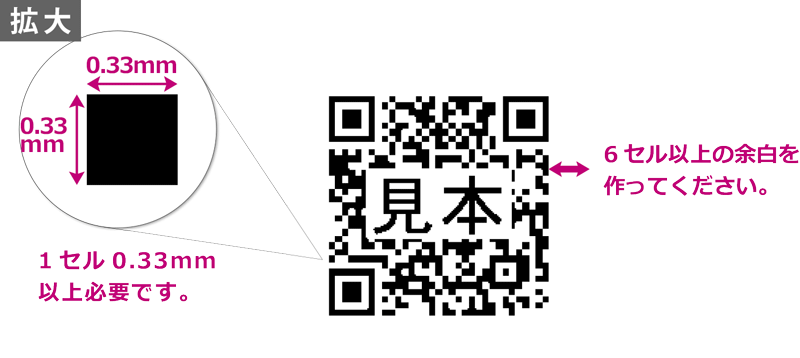

About QR code

When inserting a QR code, each cell must be at least 0.33mm, and the margin must be at least 6 cells.

Also, there must be a white space below the QR code.

Also, there must be a white space below the QR code.

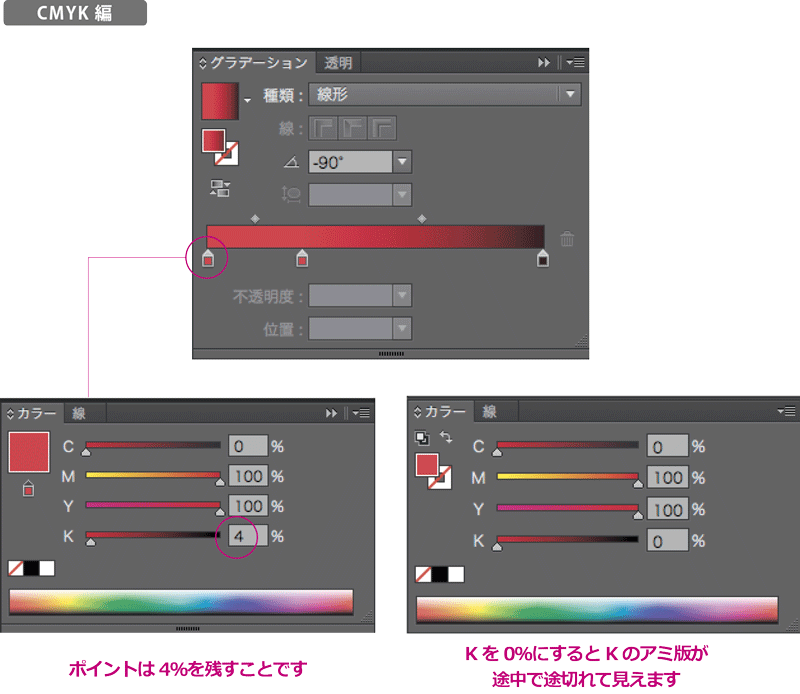

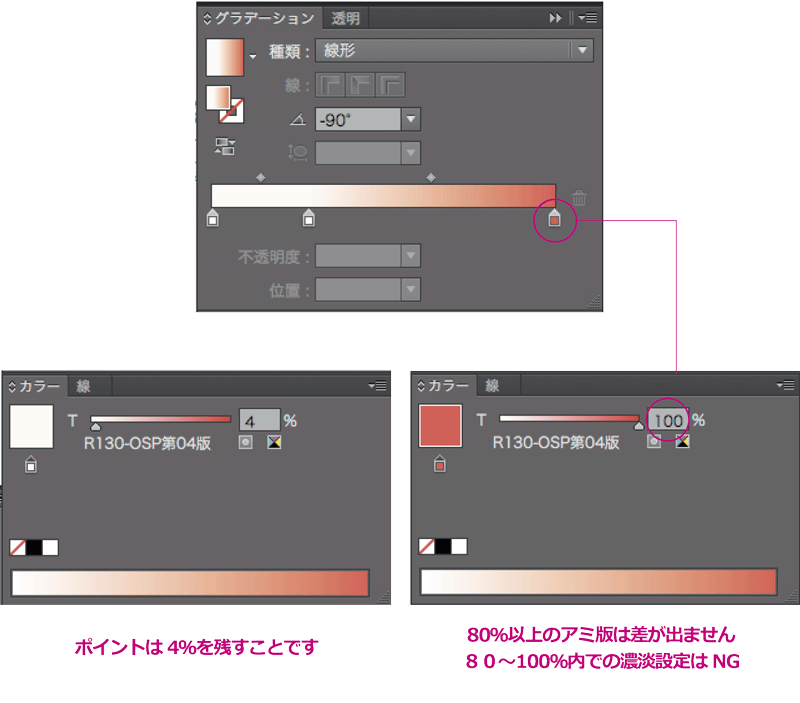

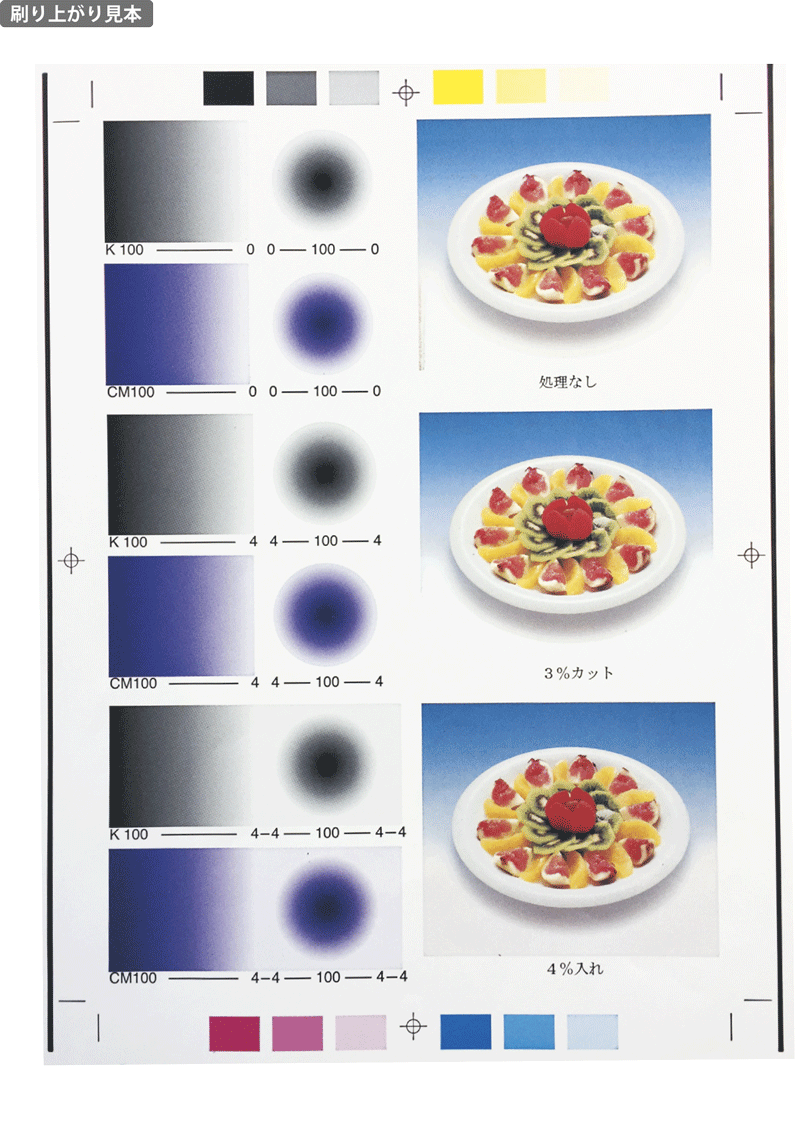

About gradient rules

The standard value for printing quality is 4% to 80%. This is because there is almost no difference when it is less than 4% and more than 80%. Therefore, if you set a gradation design that fades to white or a value that is a combination of 1% and 2%, it will not be possible to reproduce the color as per the data.

For more information, please check color proofing etc.

For more information, please check color proofing etc.

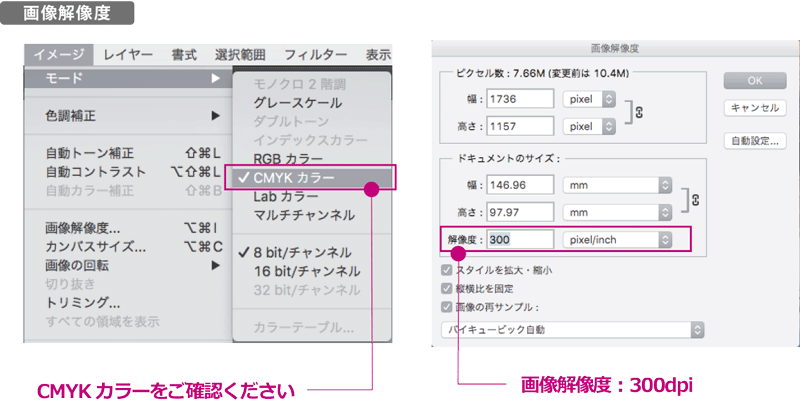

photo resolution

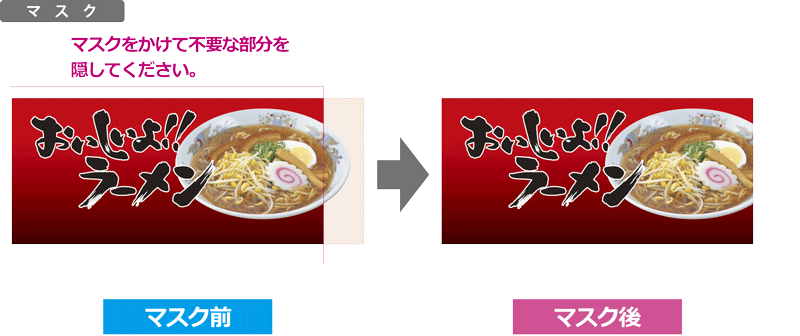

When using photographic images, please use CMYK color mode whenever possible. It is possible to print beautifully if the resolution is 300ppi or higher. If you do not mind proceeding at a low resolution of 200ppi or less, please let our sales representative know. Also, please mask or otherwise process the image to hide unnecessary parts instead of deleting them. This is necessary for processing parts that protrude from the blade shape or overlap with letters.

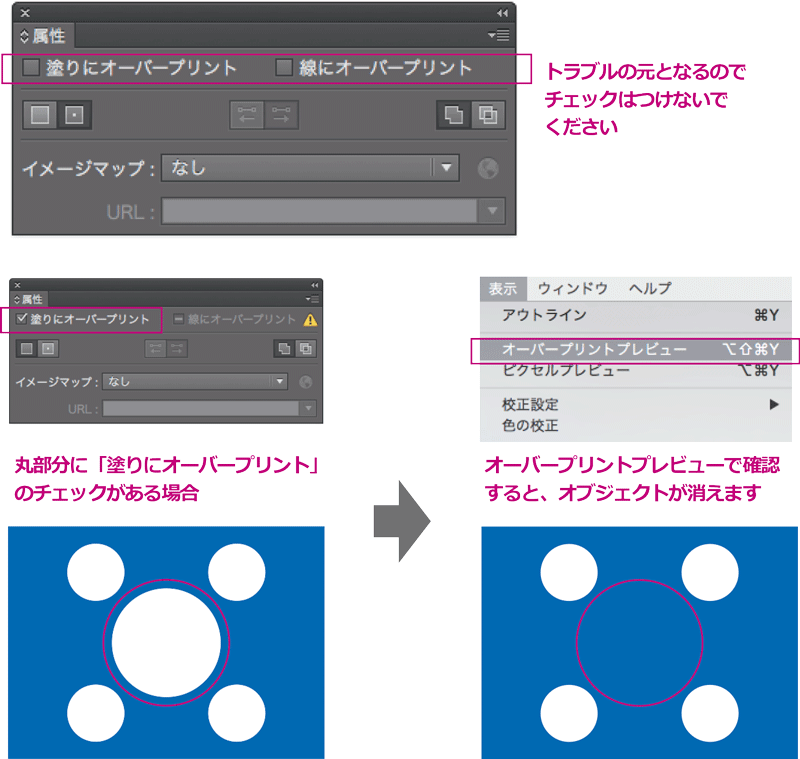

Check for overprint

If overprinting is set, the image may not be visible when printing out or creating a plate, which may cause problems such as proceeding without making the necessary plate. OSP handles all overlapping processes, so please do not use overprint settings.

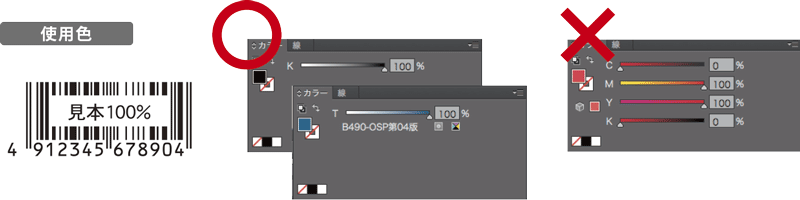

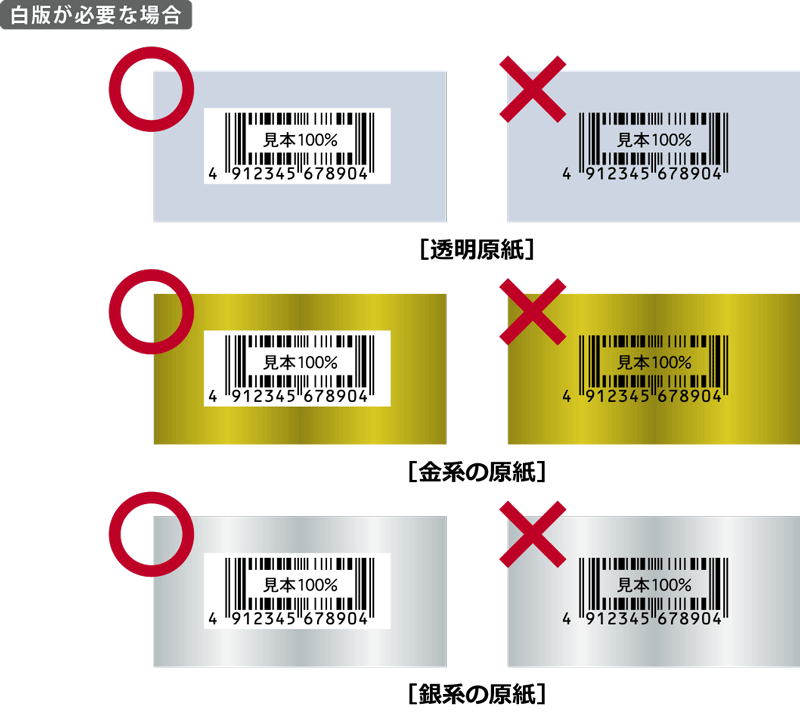

Barcode standard confirmation

Barcodes have size standards because even slight ink smudges after printing on paper can cause reading errors.

Images may not be used.

Barcodes can be reduced or enlarged from 80% to 200% of their basic dimensions.

The approximate size is 80% for 13 digits and 25mm, 8 digits for 18mm, 100% for 13 digits and 31mm, and 8 digits and 22mm.

If the progress is out of standard due to size reasons, etc., please let us know.

If you do not have barcode creation software, please specify the number and number and we will create one using OSP.

The barcode color is basically one dark color such as black or navy blue.

Combining colors and red colors that cannot be read will not be allowed.

Images may not be used.

Barcodes can be reduced or enlarged from 80% to 200% of their basic dimensions.

The approximate size is 80% for 13 digits and 25mm, 8 digits for 18mm, 100% for 13 digits and 31mm, and 8 digits and 22mm.

If the progress is out of standard due to size reasons, etc., please let us know.

If you do not have barcode creation software, please specify the number and number and we will create one using OSP.

The barcode color is basically one dark color such as black or navy blue.

Combining colors and red colors that cannot be read will not be allowed.

| Standards regarding JAN code (common items for 13 digits and 8 digits) | ||

| Multiplication rate | 80~200% | |

| bar height | 80% | 9mm or more |

| 90% | 10mm or more | |

| 100% | 11mm or more | |

| left and right margins | 4mm or more on the left side, 3mm or more on the right side | |

| bar color | "Sumi" or "Navy blue" is preferable. *Ami/crossing is not allowed, and images cannot be used. |

|

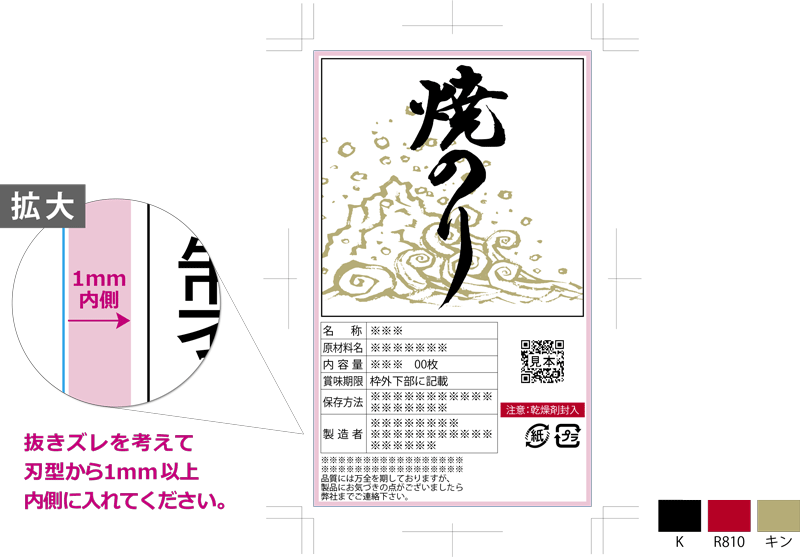

Blade mold removal confirmation

After printing, cut out the paper using the specified blade shape. At this time, not all cuts are made in the same place, and there may be slight deviations in the top, bottom, left, and right directions. Please make sure that the design area is within 1mm of the blade mold so that the pictures and letters are not chipped.

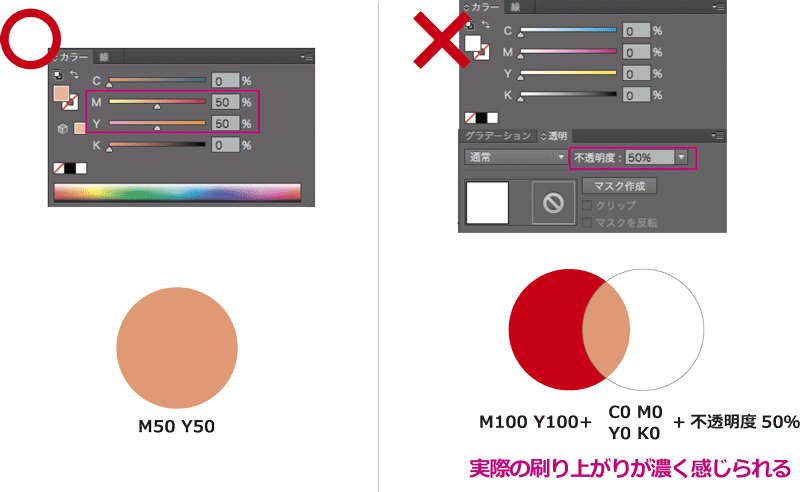

About the expression of transparency

50% red and 100% red with 50% white are similarly treated as 50% gray. However, when white is layered with transparency to create a lighter color, the actual printed color appears to be darker than the color on the screen. We recommend that you use swatches to adjust the density of the special color.