Labeller LA-8 SERIES

specification

| Model | LA-8MX Underlay machine (right flow/left flow) |

|---|---|

| processing power | 60 pieces/minute (for work pitch 335mm) |

| Number of registered breeds | Up to 2,560 varieties (Decreased depending on print data volume and number of formats) |

| Drive system | stepper motor |

| Label specification | Mounting width: 40 to 100 mm (optionally up to 150 mm) |

| Label length 40 to 110 mm | |

| Label spacing: 3mm or more | |

| Roll outer diameter ø280mm (thermal paper V8NS7, approx. 400m roll) | |

| Inner diameter of paper tube: ø76.2mm | |

| Winding specifications: front winding/reverse winding (optional) | |

| Printing specifications | Direct thermal coloring method (Thermal transfer method is optional) |

| Head density: 12 dots/mm (equivalent to 300 dpi) | |

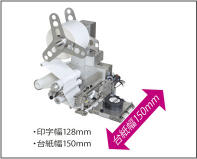

| Print width: 80mm/128mm (optional) | |

| Printing speed: 100mm/sec | |

| Conveyor specifications | Conveyor belt width: 200mm |

| Conveyor length 985mm + 150mm (discharge roller) | |

| Conveyor height 795mm (+80mm, -0mm) | |

| Conveying speed: 20.1m/min (50Hz), 24.1m/min (60Hz) | |

| interface | RS-232C, USB port, LAN port |

| External dimensions | 1,135 (width) x 770 (depth) x 1,085 (height) mm |

| Mass | about 100kg |

| Power supply/power consumption | AC100V±10% 50/60Hz・Maximum 500W |

| usage environment | Temperature: 0 to 35°C, Humidity: 30 to 85% RH (no condensation) |

| software | Dedicated label editing software is required separately |

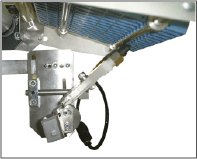

Barcode inspection system

Wide specification

■Click here for frequently asked questions!

We provide equipment tailored to your needs.

Please feel free to contact us.

Inquiry form