Paper attention/ Clear Paper Sticker

This product replaces plastic film with a paper-based material. The most unique feature is that, despite being made of paper, it has the same translucency as plastic film. It helps reduce the excessive use of plastic products.

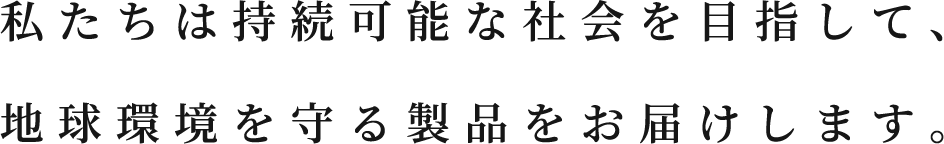

Dot Tack®

Apply glue in dot form.

It has the advantage that its adhesive strength does not decrease even if it is repeatedly stuck and peeled off.

It uses a special water-based emulsion type adhesive that does not contain organic solvents, and the surface base material is FSC® certified paper.

ES Separator

It is a release paper with a paper base material that achieves greater transparency than products using poly-laminate, even though it does not use poly-laminate. You can contribute to the reduction of environmental impact by reducing the amount of plastic used.

Kyutto Card

This shrink film has a backing card that can be used as a blister pack. It can be produced at a low cost since no molds are required, and it reduces the amount of plastic used compared to blister containers.

Clear Wrapping

It is a packaging material that does not have a backing paper, just like a separate label. It is a product that can be used as a product sticker, a sealing sticker, and a collective display sticker with a single Clear Wrapping, and can be easily separated when discarded.

Thin Labels

By thinning the surface paper and backing paper (release liner), the amount of waste can be reduced. Even with the same number of labels, the weight is lighter, which also reduces exhaust emissions during transportation.

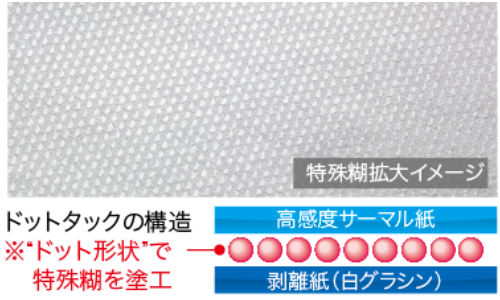

Separation label

Since it does not use a backing paper (separator), it does not generate waste. In addition, it is an eco-friendly seal label because it can roll approximately 1.5 times as many labels as labels with backing paper, even in one roll of the same lineage.

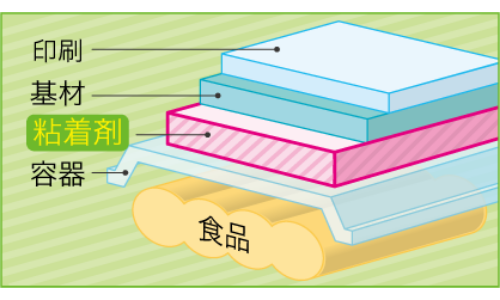

Positive List-Compliant Emulsion Adhesive

This is a tack glue for stickers and labels that uses an emulsion-type adhesive that complies with the positive list of the Food Sanitation Act.

This is a newly developed product with the aim of providing safer and more secure products.

A biomass boiler is a facility that converts waste generated during the production of seal products into fuel that can be used as heat energy within our own factories. This equipment reduces fossil fuel usage.

At OSP, we are currently in the process of replacing approximately half of our laminations with a non-solvent lamination method that does not use solvents.

The environmental impact (CO2 and VOC emissions) caused by organic solvents can be significantly reduced.

Adoption of non-sol lamination method

At OSP, we are currently in the process of replacing approximately half of our laminations with a non-solvent lamination method that does not use solvents.

The environmental impact (CO2 and VOC emissions) caused by organic solvents can be significantly reduced.

◀ Unmanned factory operating at night

◀ Unmanned factory operating at night▲A factory operating unmanned at night

Plans are in the works for an unmanned factory where AI and IoT systems are linked with POS systems nationwide to monitor the consumption of stickers, labels, and other products in real-time 24/7, and initiate order processing and printing.

The OSP Group distributed eco-bags to all of our 4,000 employees. This initiative stems from the desire for each employee to consider environmental issues more personally. The OSP Group is committed to creating environmentally friendly products and initiatives.

Distribution of Eco-bags

The OSP Group distributed eco-bags to all of our 4,000 employees. This initiative stems from the desire for each employee to consider environmental issues more personally. The OSP Group is committed to creating environmentally friendly products and initiatives.

Digital printing does not require the creation of printing plates and has no printing waste, which helps reduce waste. By using water-based inks, it also achieves reductions in VOC and CO₂ emissions.

By analyzing ordered products and promoting the use of the 30 most frequently used colors, we aim to streamline the color mixing process. We are also working to significantly reduce the amount of organic solvents used for ink cleaning.

Select 30

By analyzing ordered products and promoting the use of the 30 most frequently used colors, we aim to streamline the color mixing process. We are also working to significantly reduce the amount of organic solvents used for ink cleaning.

We promote the recycling of PET bottles by manufacturing labels using PET film that incorporates recycled PET bottles as part of the raw materials.

biomass mark

The biomass mark is a certification mark given by the Japan Organic Resources Association, a general incorporated association, to products that use organic resources derived from renewable living organisms.

(Excluding fossil resources. However, it does include inorganic resources such as shells that are produced directly by living organisms.)

| Certification body name | Japan Organic Resources Association |

|---|

| Certification number | Biomass ratio | Scope of application |

|---|---|---|

| 180099 | 20% | Film prints using biomass ink |

| 190019 | 10% | Film prints using biomass ink |

| 190020 | 10% | Stickers and labels printed using biomass ink |

| 190021 | 10% | Stickers and labels made with biomass adhesive |

| 190331 | 80% | Natural product-based self-adhesive adhesive |

FSC® Forest certification (CoC certification)

FSC ® certification is an international certification system that promotes appropriate forest management that is environmentally appropriate, socially beneficial, and economically sustainable.

| Certifying Organization | SGS Hong Kong Limited |

|---|---|

| Certification number | SGSHK-COC-002077 |

| Target department | Head Office, Yao Management Center, Tochigi Factory, Gifu Factory, Shiga Factory, Osaka Factory, Fukuoka Factory, Sales Offices, Innovation Center |

| Scope of application | Purchase FSC® forest certified paper from suppliers, manufacture and sell it, and purchase and sell forest certified products. |

biodegradable plastic

The biodegradable plastic identification labeling system is a system for clarifying the distinction between biodegradable plastic products and general plastic products. This is a certification mark that can be placed on products made of 100% biodegradable plastic.

| Certifying Organization | Japan Bioplastics Association |

|---|---|

| Certification number | Indicated together with the mark for each product |

Biomass plastic [BP]

![Biomass plastic [BP]](/outline/images/img_bp.png)

The biomass plastic identification system is a certification mark that can be indicated on plastic products with a biomass plastic content of 25% or more.

| Certifying Organization | Japan Bioplastics Association |

|---|---|

| Certification number | Indicated together with the mark for each product |