Solving complex issues by protecting product labels from harsh environments and reducing costs

| Industry/Service | : | Food manufacturing, wholesale and retail |

|---|---|---|

| Head Office Location | : | Tokyo |

MI Food Style Co., Ltd. is involved in a wide range of businesses, including the operation of high-quality supermarkets, OEM production of food products, and wholesale business. When developing a popular original soup product, the company was looking for product packaging and product display labels that could be developed in a wide variety of ways while keeping costs down. They consulted Osaka Sealing Printing (hereinafter referred to as OSP) to see if they could reduce packaging costs. We spoke to Mr. Kaneko of the Manufacturing Group, External Sales and Manufacturing Department, Product Management Headquarters, MI Food Style, who is also the company's production manager, to find out what proposal OSP made to solve the problem.

Customer Issues

- -Accurate labeling in various environments such as high temperature and freezing

- ・Increased workload due to an increase in product varieties

OSP proposal

- ・Quality design tailored to the customer's usage environment from product manufacturing

- ・One-stop service from specification proposals and design to installation of application machines

The challenge is to reduce the cost of microwaveable pouches while expanding them to a variety of products.

Please tell us about your business and how you started doing business with OSP.

Mr. Kaneko: Our company is engaged in retail business, mainly supermarkets, and the manufacture and wholesale of processed foods. The processed foods we produce are not only sold in our own directly managed stores, but are also delivered to other retailers.

The reason we consulted OSP was because we were struggling with the packaging for a new soup product we were selling. We were considering selling the soup product in a frozen state, and it would need to be cooked in a microwave or in a hot water bath. Therefore, the packaging had to be a microwave-safe pouch. Furthermore, we were planning to sell the product in a wide variety of flavors, so each product would need its own food label.

However, we wanted to keep packaging costs down while still using microwave-safe pouches, which are not cheap. Also, printing directly onto microwave-safe pouches would be costly due to the order lot size, which was a concern.

In order to solve these issues, we asked OSP if it would be possible to use the microwave-safe pouches for all products and display the products using only the labels.

We propose synthetic paper label material that can withstand freezing and high temperatures, and boil lamination processing for printing.

Could you please explain in detail how you came to adopt the label, which has the functionality to withstand temperature changes and can be used for a wide variety of products?

Mr. Kaneko: When we were faced with the challenge of keeping costs down for the microwaveable pouches, OSP proposed small-lot production using "relief printing," in which the areas to be printed, such as text information and designs, are raised, which eliminated our concerns about costs.

Furthermore, the proposal for the label specifications was also excellent. Soup products are transported and stored in a frozen state, and then cooked in a microwave or in a hot water bath. Therefore, there are many opportunities for the microwaveable pouches to get wet or form condensation, and there is a high risk that normal labels will peel off. Taking this risk into consideration, OSP proposed a water-resistant synthetic paper label material (*1).

OSP also pointed out the risk that the labels would stick to other microwaveable pouches and peel off if the products were stacked in a frozen state. To address this risk, they proposed boil lamination (*2) of the printed surface, which addressed not only the risk of the labels peeling off, but also the risk of the printed text peeling off.

*1 Water-resistant synthetic resin label material (material: synthetic paper, thickness 110μ).

*2 High-strength laminate that can withstand boiling (material: PP40, 40μ thick polypropylene laminate).

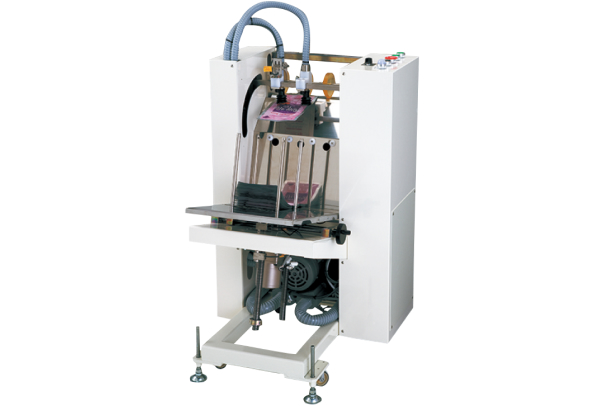

The "LA-5M Top-bottom pasting machine" is an empty pouch labeling machine that can attach labels to empty microwave-safe pouches, improving production efficiency.

You are also involved in the design and production aspects, can you tell us more about that?

Kaneko-san: OSP also proposed a design for the soup product labels that would give them a commonality that would allow us to tell that they are products of the same brand, while also expressing the characteristics of each product.

When requesting a label design for a new product, we find it helpful that they can start creating the design simply by sending us the product name and a photo of the product.

Furthermore, as the variety of products increased, OSP came up with a solution to the problem of not being able to improve production efficiency with the previous method of applying labels manually.By utilizing the "LA-5M Top-bottom pasting machine" and "AS-300II Empty Bag Feeder," which can apply labels to empty microwaveable pouches, production efficiency has improved dramatically.

We feel that a major attraction of OSP is that they can provide prompt, one-stop service not only for label specifications, but also for everything from specification proposals to design, production, and installation of application machines.

What do you expect from OSP in the future?

Kaneko-san: Currently, we are not limited to frozen soup products, but also produce a variety of other products. We are planning to develop a wide variety of new products, just like our soup products, so we hope to be able to ask for OSP's help and wisdom again when we do so. We look forward to continuing to receive the unique solution-oriented capabilities that only OSP, a comprehensive package solutions manufacturer, can provide.

About MI Food Style Co., Ltd.

As a member of the Mitsukoshi Isetan Group, we operate the food supermarket "Queens Isetan," as well as the manufacturing and development of our own original brand products, OEM business, food wholesale business, etc. We aim to contribute to enriching people's lives through "food."

Related Products

Related Products

Capable of attaching to both top and bottom surfaces at the same time The LA-5M/5M Top-bottom pasting machineattaches labels to the top and bottom surfaces of the workpiece at the same time.

Capable of attaching to both top and bottom surfaces at the same time The LA-5M/5M Top-bottom pasting machineattaches labels to the top and bottom surfaces of the workpiece at the same time. Efficient labeling of empty bags The AS-300 II Empty Bag Feederautomatically picks up empty bags one by one and feeds them to the line. By combining it with a labeler, the efficiency of labeling of empty bags can be improved.

Efficient labeling of empty bags The AS-300 II Empty Bag Feederautomatically picks up empty bags one by one and feeds them to the line. By combining it with a labeler, the efficiency of labeling of empty bags can be improved.